Muzn Energy pioneers cutting-edge pore-to-core-to-field scale solutions to revolutionize enhancement of oil and gas production. The company provides consultancy and support to oil and gas companies in areas like enhanced oil recovery, waterflood recovery, field development plans, unconventional resources optimization, CO2 storage and utilization to reduce greenhouse gas emissions as well as becoming a teaching and a learning hub for engineers and researchers in multiphase flow science.

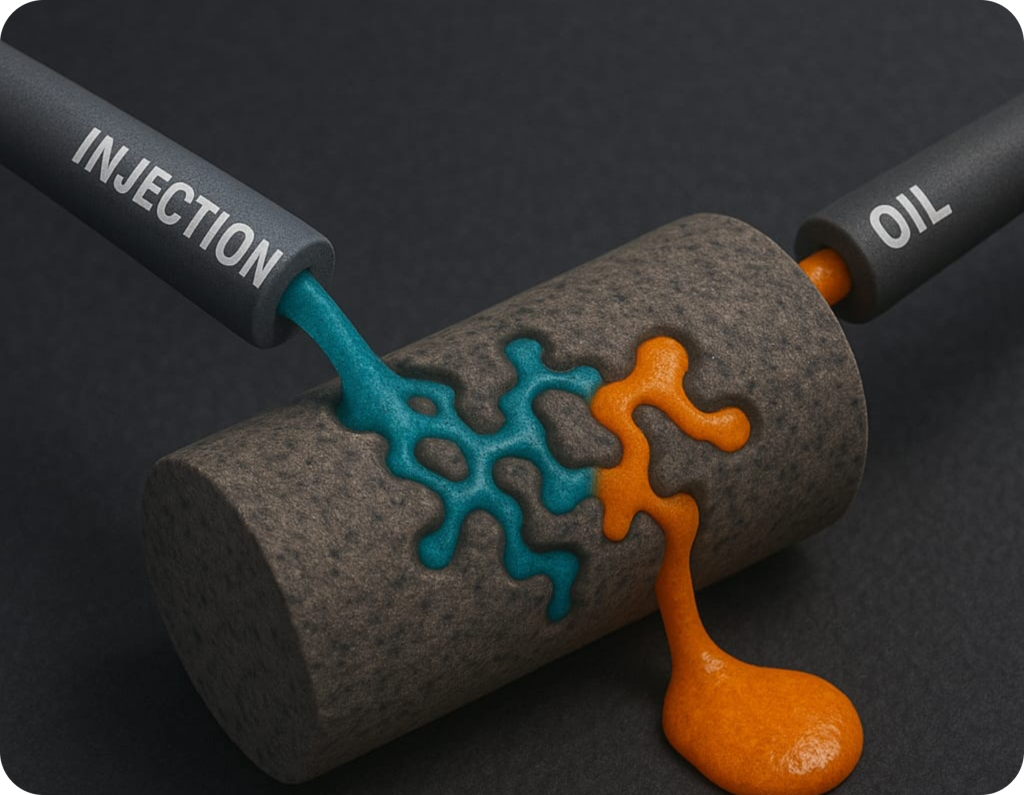

Muzn Energy pioneers cutting-edge pore-to-core-to-field scale solutions to revolutionize enhancement of oil and gas production. The company provides consultancy and support to oil and gas companies in areas like enhanced oil recovery, waterflood recovery, field development plans, unconventional resources optimization, CO2 storage and utilization to reduce greenhouse gas emissions as well as becoming a teaching and a learning hub for engineers and researchers in multiphase flow science. Muzn Energy Company is establishing a microfluidics laboratory project in the Innovation Park Muscat (IPM) as the first of its kind in the Middle East. Microfluidics technology represents a remarkable development in understanding the flow and confinement behavior of fluids in micro-channels at the micrometer scale. This pioneering technology is used in many applications in fluid transport science in porous media, mainly in the oil and gas industry, biological engineering, energy-related technologies and others.

- Our Vision

To be a leading company in providing cutting-edge laboratory services to maximize oil and gas production

- Our Mission

To revolutionize oil and gas recovery through sustainable, cost effective and innovative multi-scale laboratory and consultancy solutions

Scope and applications

Pore-Scale

Microfluidic Experiments (HPHT)

Core-Scale

Core Analysis & SCAL Services

Field-Scale

Field Development Plans

Chemical and Radio-active Tracing

Training HUB

Pore-Scale: Microfluidic Experiments (HPHT)

- Reservoir Characterization and Enhanced Oil Recovery (EOR)

- Porous Media Modeling

- EOR Screening

- Nanoparticle Transport (used in nano-EOR)

- Emulsion and Flow Assurance Studies

- Emulsion Stability

- Hydrate and Asphaltene Formation

- Produced Water Treatment

- Oil-Water Separation

- Contaminant Detection

- Digital Microfluidics for Field Applications

- On-site fluid testing

- CO2 Sequestration and Carbon Capture

- CO2-Brine Interactions

- Geological Storage Efficiency

- Frac Fluid Optimization

- Waterflood Conformance and Sweeping Optimization

Core-Scale: Core Analysis Services

- Gas and brine permeability at in situ stress-Steady-state and unsteady-state relative permeability

- Bespoke core analysis programs: polymer flooding, fracture closure, formation damage, etc.

- Capillary pressure using ultracentrifuge porous plates or humidity chambers

- Stressed and unstressed MICP-NMR-Electrical properties

- Geomechanical tests

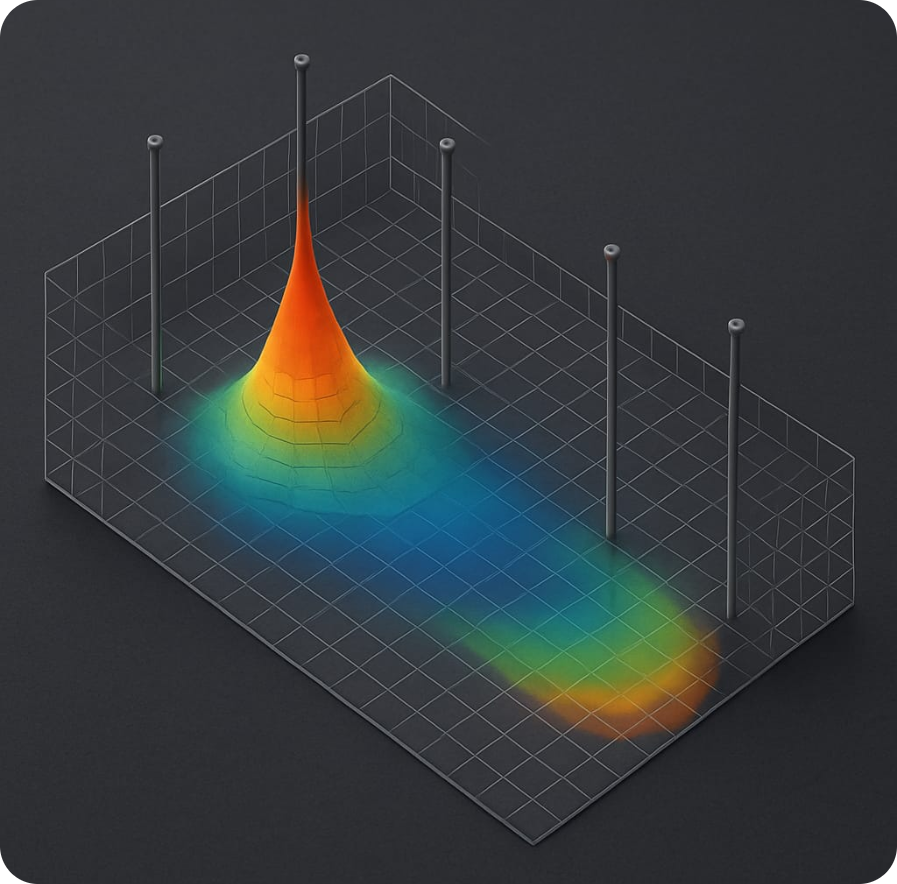

Field-Scale: Field Development Plans

Senior inter-disciplinary Omani engineers will conduct a field level studies using computer modelling and simulations to predict future performance of a reservoir under specified constraints tied to an optimal development plan. This work scope will integrate all different scale’s results to recommend the most optimum development/investment scenario for oil and gas fields.

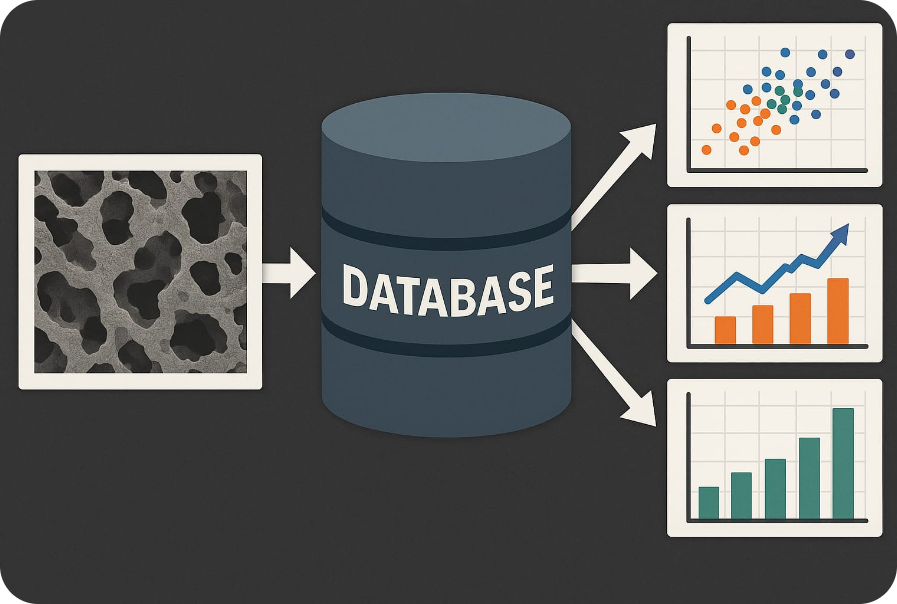

Data Mining: PETMiner

Extract more from your data with PETMiner -a sophisticated visual data analysis and data mining tool. PETMiner allows the user to better integrate and analyse microstructural and petrophysical data.

Chemical and Radio-active Tracing

Tracers are used to better understand reservoir characteristics and performance. Tracer measurements can be obtained from oil, gas, and water production via surface sampling using techniques such as gas chromatography (chemicals in water), pressure cylinders (for gas), or Geiger-Muller tubes(radioactive). Tracers can be used to :

- Obtain a clearer definition of an oil well’s fracture pattern

- Determine the most efficient waterflooding strategy, better sweep efficiency and optimum injection rates.

- Establishing flow profiles in injection wells, detecting fluid movements behind the pipe, and locating leaking packers and fluid movement between wells.